12 Apr Aluminum and its alloys

Aluminum and its alloys

Even though that him aluminum Pure is a little used material, there is the paradox that the alloys of this material are widely used in a wide variety of applications both industrially and at other levels. Therefore, we will see its classification, states and most common designations:

Classification by its process

- Forged aluminum

- Cast aluminum

Personalized treatment to resolve your concerns with our specialists.

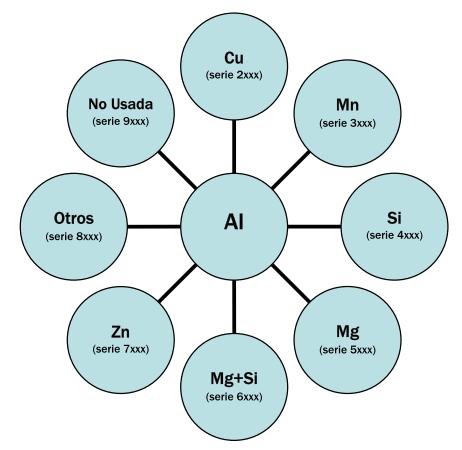

Aluminum alloys (both forged and molded) are classified according to the alloying element used (at least the one in greater proportion).

Classification by state

F: Gross state. It is the material as it leaves the manufacturing process.

OR: Annealing It is applied to both forging and casting materials that have undergone full annealing.

O1: Annealing at high temperature and slow cooling.

O2: Subjected to thermomechanical treatment.

O3: Homogenized This designation applies to wire rods and continuous casting bands, which are subjected to high temperature diffusion treatment.

W: Heat treated solution. It is applied to materials that after receiving a heat treatment remain with an unstable structure and suffer natural aging.

H: State of Acrimony. It comes with materials that have been hardened by deformation.

H1. Hardened by deformation until the desired level is obtained and without further treatment.

H2. Hardened excessively by deformation and partial annealing recover softness without losing softness.

H3. Acrimony and stabilized.

H4. Acrimony and lacquered or painted. They are cold hardened alloys that can undergo a certain annealing in the curing treatment of the given paint or lacquer layer. 7This classification uses a second digit (sometimes a third digit is necessary) that indicates the degree of strain hardening.

T: Denominates materials that have been hardened by heat treatment with or without hardening by subsequent deformation. The designations of W and T only apply to aluminum alloys already forged or cast iron that are heat treatable.

T1: Chilled from a manufacturing process carried out at a high temperature and aged naturally.

T2: Chilled from a manufacturing process performed at a high temperature, cold swallowed and naturally aged.

T3: Heat treated solution, cold worked and aged to Tamb until reaching a stable condition.

T4: Solution heat treated and aged at Tamb until a stable condition is reached. It is a treatment similar to T3 but without cold work.

T5: Chilled from a high temperature manufacturing process and artificially aged.

T6: Solution heat treated and artificially aged. Products are thus designated that after a high temperature forming process (molding or extrusion) they are not cold hardened but suffer artificial aging.

T7: Thermally treated and over-aged solution for complete stabilization.

T8: Thermally treated by dissolution, cold worked and artificially aged.

T9: Heat treated solution, artificially aged and cold worked.

T10: Chilled from a manufacturing process performed at a high temperature, cold worked and artificially aged to a substantially stable condition.

There are variants of the T state, to these variants two digits are added to the T. These two digits are specific to each product and are used for stress relief status in products manufactured through the forging process.

Aluminum series according to their alloys

Aluminum alloys (both forged and molded) are classified according to the alloying element used (at least the one in greater proportion). The most commonly used alloying elements are:

2xxx series. In these alloys the main alloying element is Cu, but sometimes Mg is also added. The characteristics of this series are: good hardness-to-weight ratio and poor corrosion resistance. With regard to the first characteristic, to say that some of the alloys in this series have to be subjected to TT solubility and sometimes aging to improve their mechanical properties.

Once this is done, the 2xxx series has mechanical properties that are of the order and sometimes higher than those of low carbon steels. The effect of TT is the increase in hardness with a decrease in elongation.

Regarding the second characteristic, these alloys are generally galvanized with high purity aluminum or with 6xxx series alloys to protect them from corrosion and so that intergranular corrosion does not occur. The most frequent uses that are given to these aluminum are (they are generally used in places where a high hardness-to-weight ratio is necessary) on the wheels of trucks and airplanes, in the suspension of trucks, in the fuselage of the airplanes, in structures that require good hardness at temperatures above 150 ºc.

Finally, say that except for the 2219 alloy, these alloys have poor weldability but very good machinability.

3xxx series. In these alloys the main alloying element is Mn. These alloys only have 20% more hardness than pure aluminum. That is because the Mn can only be added effectively in only one 1.5%.

Therefore there are very few alloys of this series. However, aluminum 3003, 3 × 04 and 3105 are widely used to manufacture utensils that need medium hardness and that good workability is necessary to manufacture them such as bottles for drinks, kitchen utensils, heat exchangers, furniture, traffic signs, roofs and other architectural applications.

4xxx series. In this series, the main alloying element is Si, which is usually added in moderately high quantities (above 12%) to achieve a decrease in the melting range of the alloy. The objective is to achieve an alloy that melts at a lower temperature than the rest of the aluminum alloys for use as a welding element.

These alloys in principle are not heat treatable but if they are used in welding to weld other alloys that are heat treatable part of the alloying elements of the heat treatable alloys go to the 4xxx series and make a part of the alloy heat treatable.

Alloys with a high Si level have a range of colors ranging from dark gray to carbon color and are therefore being demanded in architectural applications. The 4032 has a low coefficient of thermal expansion and high wear resistance, which makes it well placed for use in engine piston fabrication.

5xxx series. This series uses Mg as the main alloying element and sometimes small amounts of Mn are also added, whose objective is to harden the aluminum. Mg is an element that hardens aluminum more than Mn (a 0.8 of Mg produces the same effect as a 1.25 of Mn) and also more Mg can be added than Mn.

The main characteristics of these alloys are medium to high hardness due to strain hardening, good weldability, good resistance to corrosion in the marine environment and a low capacity for cold work. These features make these alloys used for decorative, ornamental and architectural ornaments, in the home, street and road lighting, boats, ships and cryogenic tanks, crane bridge parts and car structures.

6xxx series. In these alloys, Mg and Si are used as alloying elements in suitable proportions for Mg2Si to form. This makes this alloy heat treatable. These alloys are less resistant than other alloys, in return it also has formability, weldability, machinability and corrosion resistance.

These alloys can be modeled by a TT T4 and hardened by a series of actions that complete the TT T6. Its use is usually that of architectural applications, bicycle frames, bridge railings, transport equipment and welded structures.

7xxx series The Zn added in proportions ranging from 1 to 8 % is the alloying element in greater proportion in these alloys. Sometimes small amounts of Mg are added to make the alloy heat treatable.

It is also normal to add other alloying elements such as Cu or Cr in small quantities. Because the main property of these alloys is their high hardness is often used in the structures of airplanes, mobile equipment and other highly forced parts.

Because this series shows a very low resistance to corrosion under tension, a TT is usually applied slightly to achieve a better mixture of properties.

Personalized treatment to resolve your concerns with our specialists.

You may also be interested in articles on Aluminum Types and Our Products.

We assist you in everything you need to Aluminum

Personalized treatment to resolve your concerns with our specialists.

Contact us

Send us your question by filling out the form and we will respond as soon as possible. You can also contact us directly through WhatsApp or call our phone number.