AmesPore Sintered Porous Metal Filters and Components

Available formats: Disks, Candles and Tubes, Rings, Plates and Membranes.

The AmesPore porous metal components and filters® they are sintered metal parts with great porosity, between 25 and 60% in volume, stainless steel or bronze.

They are manufactured by powder metallurgy technology, consisting of forming a mixture of metallic powders in a mold or tooling with the shape of the negative part, and sintering the resulting preform. The preform can be created by gravity filling, by uniaxial compaction, by isostatic compaction or by extrusion, depending on the material to be formed, the porosity to be achieved and the geometry of the component.

Sintering consists in heating the preform to a temperature below the melting point of the base metal (between 700ºC and 1,300ºC), in controlled atmosphere and time. The temperature causes the welding of the dust particles together.

The result of the sintering process is a structurally functional metal part with a controlled level of microporosity.

Advantages of AmesPore® sintered metal filters

High filtering efficiency

The total porosity and the pore size are variable, achieving filtering efficiencies from 0.02 µm to 270 µm depending on the material.

Great regularity of behavior

Since the level of porosity is homogeneous throughout the volume of the filter.

Variable wall thickness from 0.5 mm

This advantage makes the fluid travel an intricate path inside the filter, which acts throughout its section as a depth filter.

Mechanical, thermal and chemical resistance

? They can work under temperature and pressure without deforming or degrading. They are resistant to impact (no fragility).

? They have good chemical resistance: they resist corrosion under a wide range of liquids and gases, especially those made of stainless steel.

? They behave as self-supported structural elements thanks to their high rigidity.

Reusable and adaptable

? They are reusable, and therefore their useful life is high. It can be cleaned by countercurrent or with solvents.

? They are weldable and machinable, so they can be adapted to specific mounting.

? They can have complex shapes, especially bronze filters, integrating functions added to the filter function.

What are AMESPORE® filters used for?

FLUID FILTRATION

The porosity is capable of retaining the solid particles contained in a liquid or gaseous fluid, and partially separating liquid and solid phases or gaseous phases of different molecular weight. This property is used to filter fluids of very diverse characteristics.

PRESSURE FALL

Porosity reduces the pressure of the fluid that passes through it, this phenomenon being known as pressure loss. This phenomenon is used to dampen the sound of pressurized gases (Silencers) or to protect hydraulic equipment and electronic devices.

FLOW CONTROL

Porosity allows the passage of a fluid through it to have a constant flow at the exit of the porous piece, especially if the flow is generated by capillarity. In this way a very precise control of the output flow of fluids stored under pressure is achieved.

AIR / FLUIDIFICATION

The passage of pressurized gas through the porosity results in a constant and controlled gas flow rate at the outlet of the porous component and distributed with the same pressure at all points. In this way, liquids can be gasified or aerated, provide a constant gas flow rate, or manipulate powder solids by fluidization.

ANTI HUMIDITY

Porosity is able to retain and condense the moisture contained in a gas that passes through it. This property is used to dry and to protect devices against corrosion.

FLAME ANTIRRETURN

The presence of a porous component before a flame prevents the flame from being able to recede. The usual applications are gas boilers, heaters, welding facilities, etc.

Usual applications

CHEMISTRY

Petrochemical industry, water purification, nuclear facilities, heat exchangers, ozonation, transport of chemical powders, recovery of catalysts, drying in general, general, manufacture of chemical products, pharmaceutical industry, hydrogen purification, etc.

FEEDING

Gasification of liquids and liquors, evaporators, fluidization and transport of powder solids, packaging manufacturing, dairy industry, bacterial ultrafiltration, etc.

INDUSTRIAL

Pneumatic and hydraulic circuits (compensators, traps, regulators, silencers), protection of sensors and gauges, geared motors, pneumatic cylinders, welding, industrial gases, industrial filtration, extinguishers, molds, sprayers, boiler, etc.

TRANSPORT

Automotive, marine, aviation, railways, etc.

APPLIANCES / HOME

Boilers, heaters, gas burners, printers, etc.

OTHER SECTORS

Aquariums, underwater fishing, clinical analysis, medicinal gases, protection of electronic equipment, energy, personal care, measuring equipment, diverse machinery, etc.

Available forms

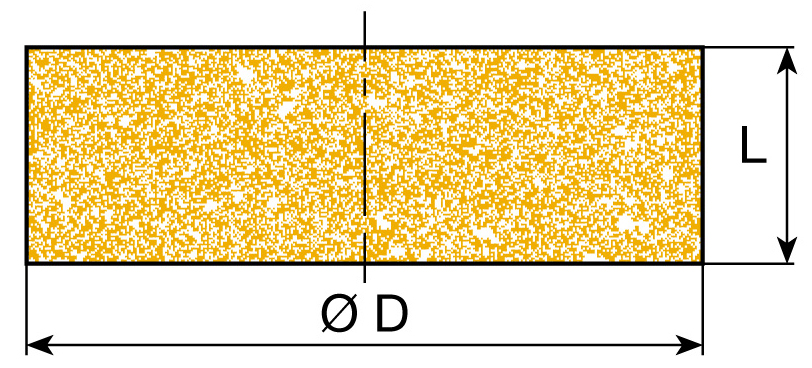

Bronze AmesPore® B filter discs with permanent stock

The material of these filters is bronze 89/11, which contains an 89% Copper and a 11% Tin.

Bronze filters are manufactured by filling a mold with spherical bronze particles and subsequent sintering of the preform.

The pore size is adjusted by selecting the particle size.

Designation

A sintered porous disc AmesPore® bronze 89/11 with a filter efficiency of 200 µm, and with external Ø measures of 10 mm and length of 4 mm, is designated as:

AmesPore® B200 D-10-4

(letter B indicates bronze, and letter D indicates disk)

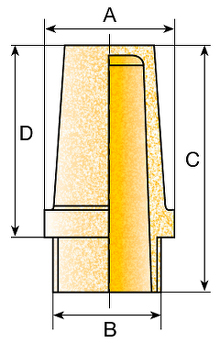

AmesPore®STC silencers with self-locking porous thread

AmesPore® silencers are sintered porous bronze elements that are used to reduce the output pressure of a compressed gas, thus preventing noise from occurring during gas evacuation.

The material used for its manufacture is Bronze B85. AmesPore® standard silencers are delivered bagged with airtight closure. AMES has a permanent stock of standard silencers.

Designation

A sintered bronze silencer AmesPore® with ¾ self-locking porous thread? It is designated as:

AmesPore® STC? ¾

(STC letters indicate muffler with self-locking porous thread)

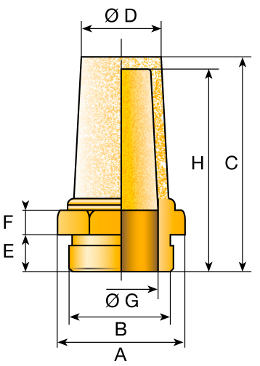

AmesPore® SLC silencers with solid brass BSP thread

AmesPore® silencers are sintered porous bronze elements that are used to reduce the output pressure of a compressed gas, thus preventing noise from occurring during gas evacuation. The material used for its manufacture is Bronze B85.

AmesPore® standard silencers are delivered bagged with airtight closure. AMES has a permanent stock of standard silencers.

Designation

A sintered bronze silencer AmesPore® with ½ solid brass thread? It is designated as:

AmesPore® SLC? ½

(SLC letters indicate silencer with solid brass thread)

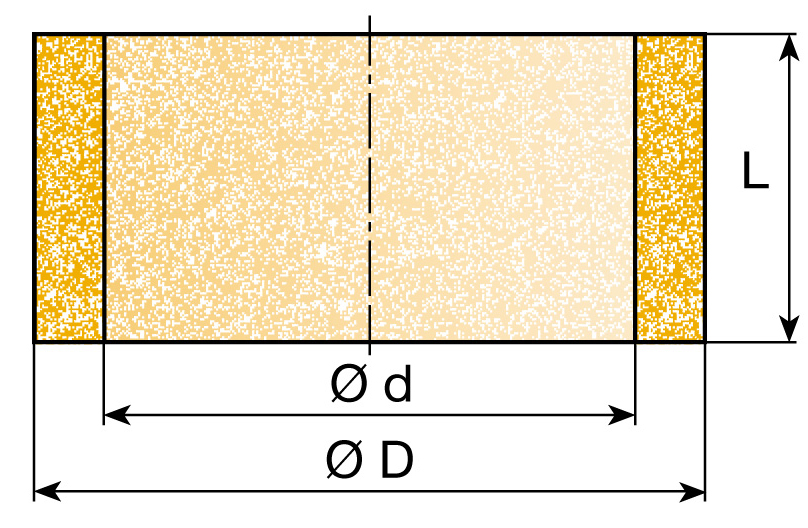

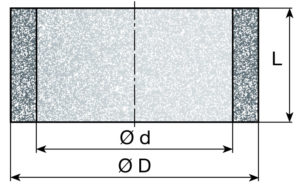

Bronze AmesPore® B filter rings

The material of these filters is bronze 89/11, which contains an 89% Copper and a 11% Tin. Bronze filters are manufactured by filling a mold with spherical bronze particles and subsequent sintering of the preform.

The pore size is adjusted by selecting the particle size.

Designation

A sintered porous ring AmesPore® bronze 89/11 with a filter efficiency of 60 µm, and with external Ø measures of 24 mm, internal Ø of 20 mm and length of 32 mm, is designated as:

AmesPore® B60 R-24-20-32

(letter B indicates bronze, and letter R indicates ring)

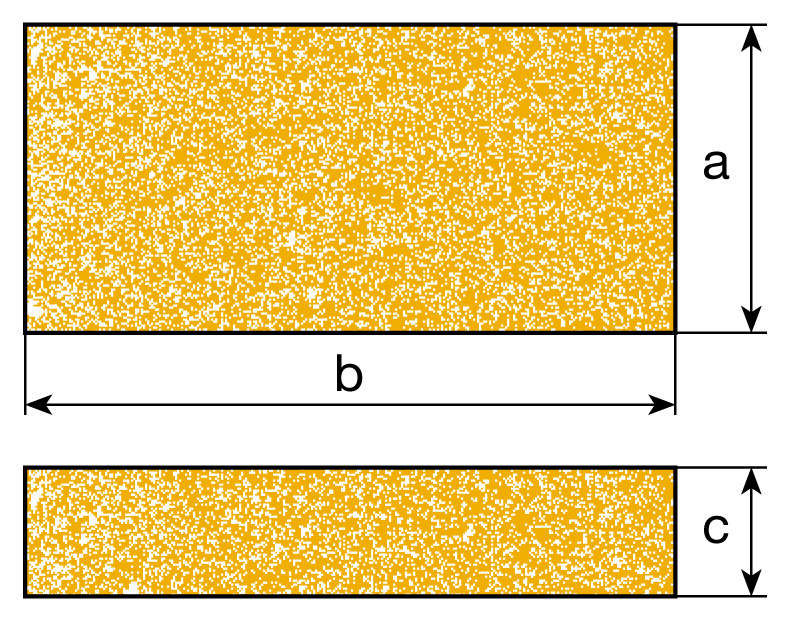

Bronze AmesPore® B filter plates

The material of these porous plates is bronze 89/11, which contains an 89% of Copper and a 11% of Tin. Bronze filters are manufactured by filling a mold with spherical bronze particles and subsequent sintering of the preform.

The pore size is adjusted by selecting the particle size.

Designation

A sintered porous plate AmesPore® bronze 89/11 with a filter efficiency of 10 µm, and measures 1,000 mm wide, 150 mm long and 5 mm high, is designated as:

AmesPore® B10 P-1000-150-5

(letter B indicates bronze, and letter P indicates plaque)

Bronze AmesPore® B filter plates

The material of these porous plates is bronze 89/11, which contains an 89% of Copper and a 11% of Tin. Bronze filters are manufactured by filling a mold with spherical bronze particles and subsequent sintering of the preform.

The pore size is adjusted by selecting the particle size.

Designation

A sintered porous plate AmesPore® bronze 89/11 with a filter efficiency of 10 µm, and measures 1,000 mm wide, 150 mm long and 5 mm high, is designated as:

AmesPore® B10 P-1000-150-5

(letter B indicates bronze, and letter P indicates plaque)

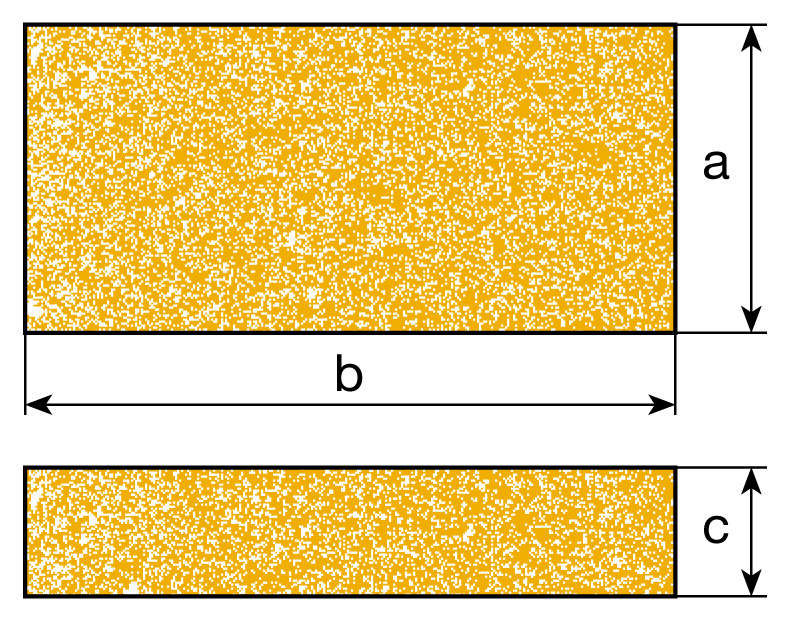

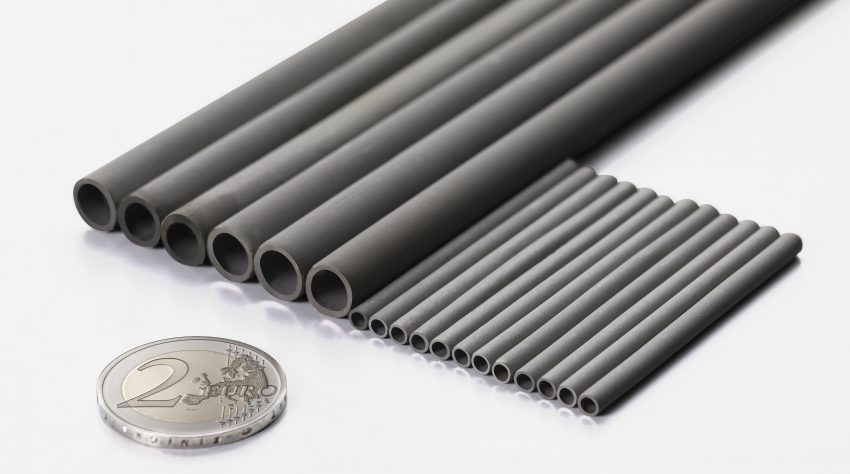

Sail filters and porous pipes AmesPore® SSI stainless steel

AmesPore® Candle Filters and Porous Tubes are cylindrical filters of small wall thickness and length, therefore, with a high length-diameter ratio.

The material of these filters is AISI 316L stainless steel. The pore size is adjusted by modifying the compaction pressure and / or the particle size of the powder.

They are commonly used in microfiltration of gases at high temperature or pressure, and of liquids in tangential filtration. It is usual to incorporate connections of different geometries to the ends (standard or under specific customer requirement).

Designation

A sintered candle filter AmesPore® AISI 316L stainless steel with an average pore size of 2.5 µm, with measures Ø outer 20 mm, inner Ø 16 mm and length 250 mm, is designated as:

AmesPore® SSI2 C-20-16-250

(SSI letters indicate isostatically compacted stainless steel and letter C indicates candle filter)

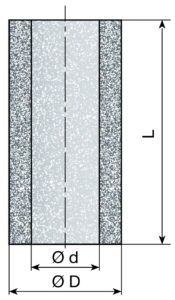

AmesPore® SSU stainless steel filter discs

The material of these filters is stainless steel AISI 316L or AISI 316. They are manufactured by uniaxial compaction of powder in a rigid tooling with the shape of the negative of the piece, and subsequent sintering. The pore size is adjusted by modifying the compaction pressure and / or the particle size of the powder.

They are commonly used in microfiltration of gases and liquids in depth filtration.

Powder metallurgy technology is capable of creating blind rings and other special geometries, for applications such as silencers or flame backstop, building a specific tooling according to the required design.

Designation

A porous sintered disk AmesPore® 316L stainless steel with a filtration efficiency of 20 µm, and with external Ø measures of 16 mm and length of 3 mm, is designated as:

AmesPore® SSU20 D-16-3

(The letters SSU indicate uniaxially compacted stainless steel, and the letter D indicates disc)

AmesPore® SSU stainless steel filter rings

The material of these filters is stainless steel AISI 316L or AISI 316. They are manufactured by uniaxial compaction of powder in a rigid tooling with the shape of the negative of the piece, and subsequent sintering. The pore size is adjusted by modifying the compaction pressure and / or the particle size of the powder.

They are commonly used in microfiltration of gases and liquids in depth filtration.

Powder metallurgy technology is capable of creating blind rings and other special geometries, for applications such as silencers or flame backstop, building a specific tooling according to the required design.

Designation

A sintered porous ring AmesPore® Made of stainless steel AISI 316L or AISI 316 with a filtration efficiency of 10 µm, and with measures Ø outer of 20 mm, inner Ø of 16 mm and length of 20 mm, it is designated as:

AmesPore® SSU10 R-20-16-20

(The letters SSU indicate uniaxially compacted stainless steel, and the letter R indicates ring)

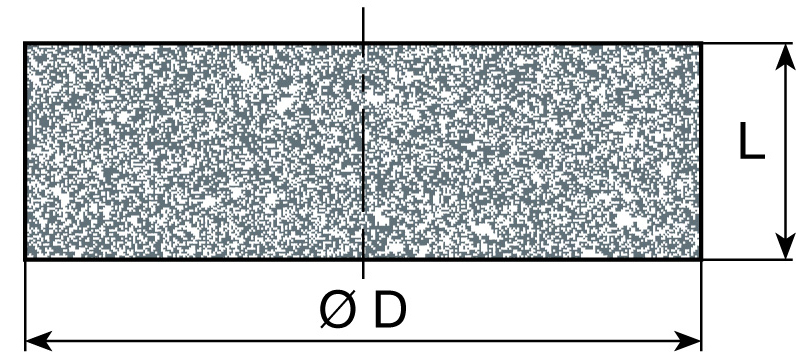

AmesPore® XPM stainless steel metal membranes

The AmesPore® XPM metal membranes are an innovative sintered product, consisting of a porous metallic core of 316L stainless steel of small wall thickness (0.5? 1.0 mm), whose inner diameter is covered by a thin ceramic layer of size very small pore (up to 20 nm).

These characteristics allow the use of AmesPore® XPM metal membranes in ultrafiltration facilities for the food industry (beverages, dairy, etc.), pharmaceutical, chemical, petrochemical, or wastewater treatment among other applications.

The AmesPore metal membranes® XPM present the great advantage in front of ceramic membranes of being resistant and tenacious against mechanical or thermal shocks, providing security in its handling, transport and assembly, safety against pressure and temperature peaks, and a great resistance to thermal fatigue.

Compared to other metal membranes currently on the market, AmesPore membranes® XPM provide as an advantage its small tube diameter with a low wall thickness (<1 mm). This differentiating feature makes it possible to greatly reduce the volume of the filter installation, from 2 to 6 times depending on the size of the tube, thus resulting in a smaller and more economical installation for the same performance.

AmesPore metal membranes® XPM is marketed in the form of filter modules, designed jointly with the customer according to their specific needs. The following tables show some examples of dimensions and characteristics of AmesPore metal membranes® XPM, and module specifications for tests.

Bronze filters with specific shape

AMES offers its customers the possibility of manufacturing filters and porous bronze components with specific shapes, as a complement to the standard shapes shown in the previous pages of this catalog.

Each of these special applications requires a specific mold to achieve the desired geometry and pore size. The mold is designed and built entirely in AMES.

The following images show various examples of sintered bronze porous components with geometry specifically designed for a particular function or equipment, which are used for very diverse applications.

Formats

- AmesPore filter discs® SSU stainless steel

- Sail filters and porous tubes AmesPore® SSI stainless steel

- AmesPore filter rings® SSU stainless steel

- AmesPore filter discs® Bronze b

- AmesPore filter rings® Bronze b

- AmesPore filter plates® Bronze b

- AmesPore stainless steel metal membranes® XPM