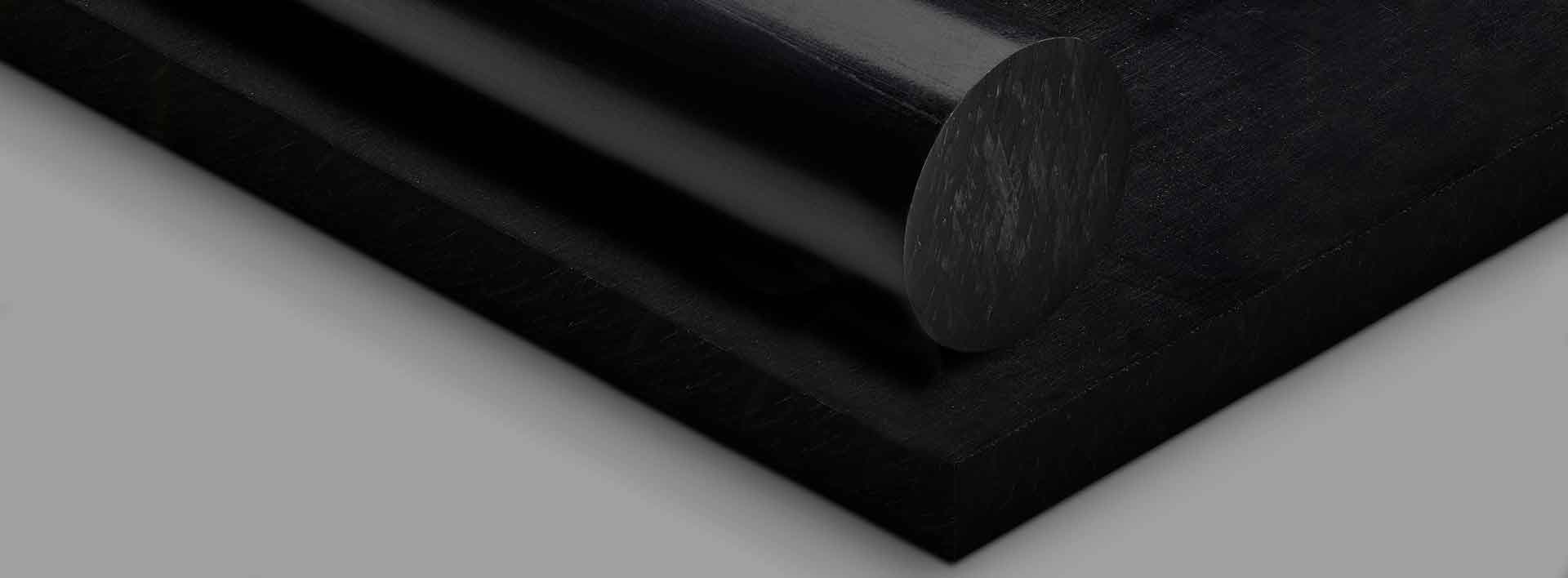

NYLOTRON | PA6 + MoS2

Available formats: Bars, Tubes, and Plates

Nylotron or PA6 + MoS2 is a polyamide with excellent qualities, such as hardness, shock absorbing, noise, vibration, wear resistance, abrasion resistance, etc. It is capable of withstanding dynamic loads, is quite resistant to heat and has good resistance against some chemical materials.

He Polyamide 6 + MoS2 It is a thermoplastic material whose quality and degree of crystallization have been improved.

It is a polyamide loaded with molybdenum bisulfide, which acts as a solid lubricant, with the advantage that it absorbs less moisture than normal polyamide, also giving it very good sliding properties, with high wear resistance. Thus, it does not require lubrication, and is suitable for multiple applications. It has an easy mechanization with very good dimensional stability.

Applications

Construction of machinery, automotive, transport, gears, clutches and motor propellers, machinery for paper companies, textile and packaging sector, printing machinery, precision mechanics, power tools and agricultural machinery.

Examples of applications:

- Sliding plates

- Parts for various machinery

- Bearing edges

- Throat pulleys

- Rolling pulleys

- Protectors and shock absorbers

- Bearings

- Gears

- Mold release devices

- Chain driven wheels

Physical Properties

| Physical Properties | Rule | Units | Values |

|---|---|---|---|

| Specific weight | ISO 1183 | g / cm3 | 1,15 |

| Water absorption upon saturation | ISO 62 | % | 8 |

| Moisture absorption at 23 ° C? 50% RH | ISO 62 | % | 3 |

| Upper limit of working temperature | - | ºC | 105 |

| Lower limit of working temperature | - | ºC | -30 |

Mechanical properties

| Mechanical properties | Rule | Units | Values |

|---|---|---|---|

| Elastic limit (2) | ISO 527 | MPa | 75 * |

| Elongation in performance (2) | ISO 527 | % | - |

| Tensile strength until breakage (2) | ISO 527 | MPa | - |

| Elongation to breakage (2) | ISO 527 | % | 25 * |

| Traction Module (2) | ISO 527 | MPa | 2700 * |

| Impact resistance without notches | ISO 179 | KJ / mm2 | - |

| Notched Impact Resistance | ISO 179 | KJ / mm2 | - |

| Rockwell hardness M | ISO 2039 | N / mm2 | - |

| Shore D hardness | DIN 53505 | ° Shore D | 80 |

| Flexural strength - at 3.5% | ISO 178 | MPa | - |

| Flex module | ISO 178 | MPa | - |

| Compressive tension (1% voltage-23 ° C) | ISO 604 | MPa | - |

| Compression module | ISO 604 | MPa | - |

| Deformation under load 100 Mpa-24 hr- RT | - | % | - |

| Poisson relationship | Abs | - |

(1) For a tension-free resistance of 5000 h: approximate reduction of the value in 1000 hours to 50% of the tensile strength. (2) Stabilized in air at 50% relative humidity. (*) Drying / stabilizing in the atmosphere 50% HR -23 ° C. (**) Stabilizing in the atmosphere 50% HR -23 ° C. (***) Resistance to UV exposure is achieved with pigmentation or specific additive. (****) Bonding and painting are possible after a special surface treatment. The data shown in this table have been determined in our laboratories and should only be considered as a useful reference; They did not commit for us in the different forms of application. As a result of our technological experience and our best knowledge, the data offers an initial evaluation of the polymer. This data cannot be applied to finished parts as obtained under specific conditions and is only an average value. Values should be considered a useful reference and are given without compromise.

Formats

- NYLOTRON Bars

- NYLOTRON Pipes

- NYLOTRON plates

Specialized Technical Advice

We have specialized staff with extensive experience in the sector for any specific advice they need.